Latest sewage & wastewater news

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Directional Drilling – the future of mains sewer connections?

Are you looking for an experienced, reliable, comprehensive and qualified wastewater company to carry out your connection to mains sewer?

If so, you are in the right place!

R A Dalton carry out a wide variety of connection jobs on a monthly basis for both domestic and commercial customers, we have see our enquiries to cover this scope of works increase seven-fold over the last couple years and even doubled in the last 12 months.

Following the introduction and implementation of the 2020 General Binding Rules we have found that more customer are having to pursue this option to handle their waste and surface water drainage. The vast development of the sewer network has meant that this option is becoming more viable for some rural areas which have always previously relied on off-mains drainage solutions such as Sewage treatment plants, septic tanks and cess pits.

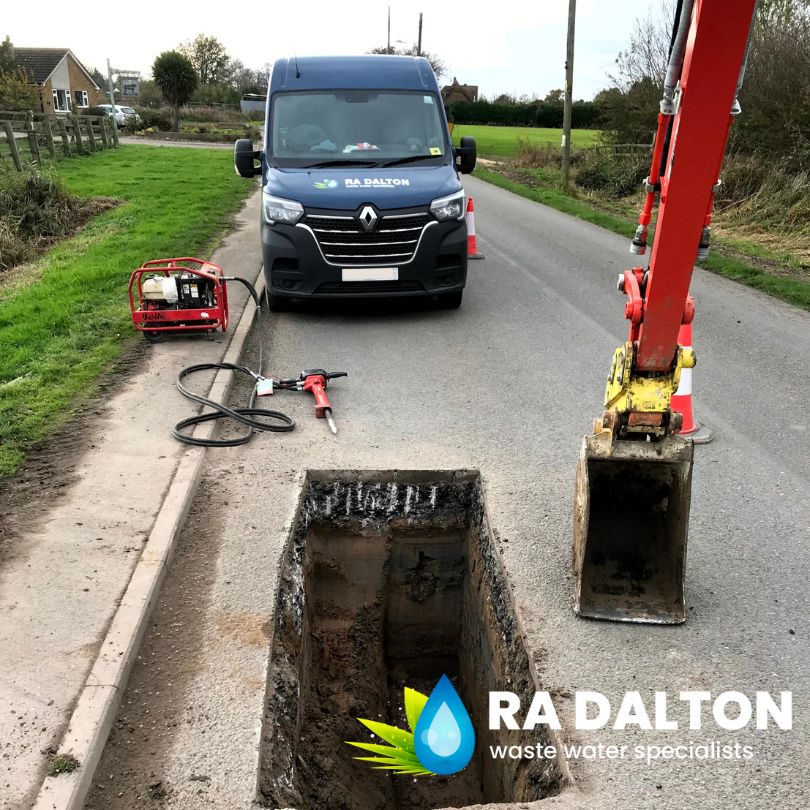

Connection to mains sewer projects

As a company we have a team of onsite and office staff dedicated to ensuring your installation is carried out not only to a high standard but also done legally and using all the correct channels (you may or may not be surprised to hear that this is not the case for all contractors).

Our first port of call when receiving an enquiry for a new project is to attend site to discuss the requirements, take some details including but not limited to topography of the site, initial insight on the expected ground conditions, any environmental matters to take into consideration, invert levels of any existing drainage and approximate distance to the mains sewer.

This is likely to also require the procurement of sewer and other services maps to understand what is installed below ground level. For a number of our more complex and expansive sites we have started to promote the use of Directional Drilling.

Directional Drilling – The Pros and Cons

When we are determining each individual site’s requirements we always look at the options available to us, for some sites directional drilling would be a preferred option whereas others it would be considered an unnecessary additional expense.

Pros:

- If you are requiring a large amount of pipework to be installed a drilling rig will only need a fraction of the time manual excavation takes. For some of our recent projects where the meterage of pipework required is into the thousands this would take weeks if not months to excavate whereas using directional drilling had it installed in just under 2 weeks.

- Directional drilling will reduce reinstatement costs when working in the highway as you will not need to re-tarmac all the trenches and only the launch pits and connection points instead.

- This is also the ideal solution when you are wanting to limit any excavation works either due to environmental or ecological concerns or just want to reduce the impact of heavy machinery in the installation area (please note excavation work is still required even with directional drilling).

Cons:

- If there are a lot of buried services within the working area then directional drilling may not be the preferred option as you will be extremely limited on how close to some services you can drill next to. However if the scale of impact is minimal you will still be able to directional drill to and from a certain point with a reduced requirement for manual excavation.

- Due to the nature of drilling further surveys may be required such as a radar survey which further pinpoints where services are located under ground.

Whilst it feels unfair to allocate this to a con, the drilling rigs are also impacted by the ground conditions and much in the way that machine excavation could require shoring or the use of a breaker, the rig may require different tools to enable the job to work efficiently.

If you are unsure if this could be the solution you are looking for why not give our offices a call on 01388 537030 for more information!