RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Efficient Wastewater Solution for Growing Business: BG BioDisc 1100mm invert and DPSAL2 Twin Effluent Pump Station

The Challenge: An Overloaded System

At a recent site on Northallerton, expansion brought an unforeseen challenge—the existing Klargester BC BioDisc wastewater treatment system was no longer sufficient. As the number of staff, visitors, and café patrons grew, the system struggled to keep up, leading to frequent flooding and occasional backups in the outfall pipe. The decision was reached to introduce a pumped outlet to remove this issue and provide a sustainable long term solution.

The Solution: Upgrading with a Klargester BG BioDisc

Our installations team took on the task of designing and upgrading the system. After a detailed assessment, the appointed contracts manager proposed the installation of a larger Klargester BG BioDisc, positioned alongside the redundant tank. This would work in tandem with a new final effluent pumping station, ensuring that wastewater could be managed effectively without overloading the existing outfall chamber.

Project Planning and Preparations

The project required careful planning. To allow machinery access, a section of fencing had to be removed, and once work was complete, it would be reinstated. With regulatory compliance in mind, rainwater outlets were inspected to ensure they were separate from the foul drainage system. Power supply modifications were also necessary by adapting the existing connection.

Installation Process

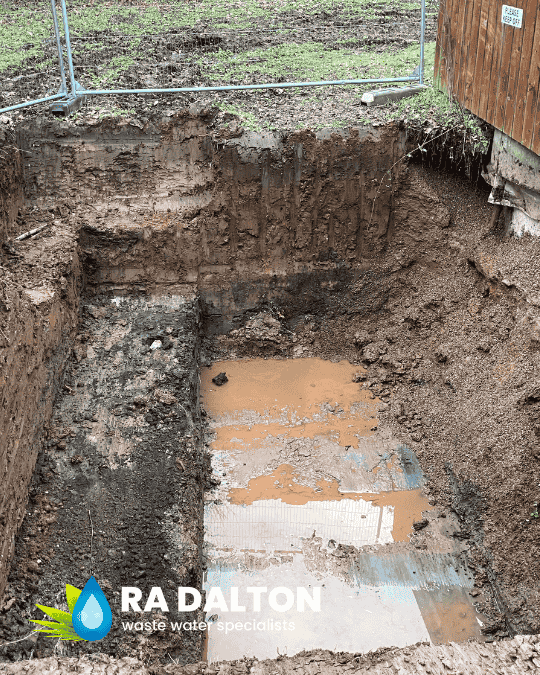

Once the groundwork was prepared, the installation commenced. The Klargester BG BioDisc was carefully set in a full concrete surround, with two inlet inspection chambers and new pipework laid to integrate from the existing system. The DPSAL2 Twin Pump Effluent Chamber was then installed, ensuring that final effluent could be efficiently discharged without risk of backups. With precise coordination, the new system was connected to the existing infrastructure, while outdated components of the old system were safely decommissioned.

Challenges were anticipated and managed. The excavation process revealed conditions that required contingency planning—hard rock demanded specialist equipment. These possibilities were accounted for in advance, ensuring that work proceeded smoothly with minimal delays.

Completion and Final Commissioning

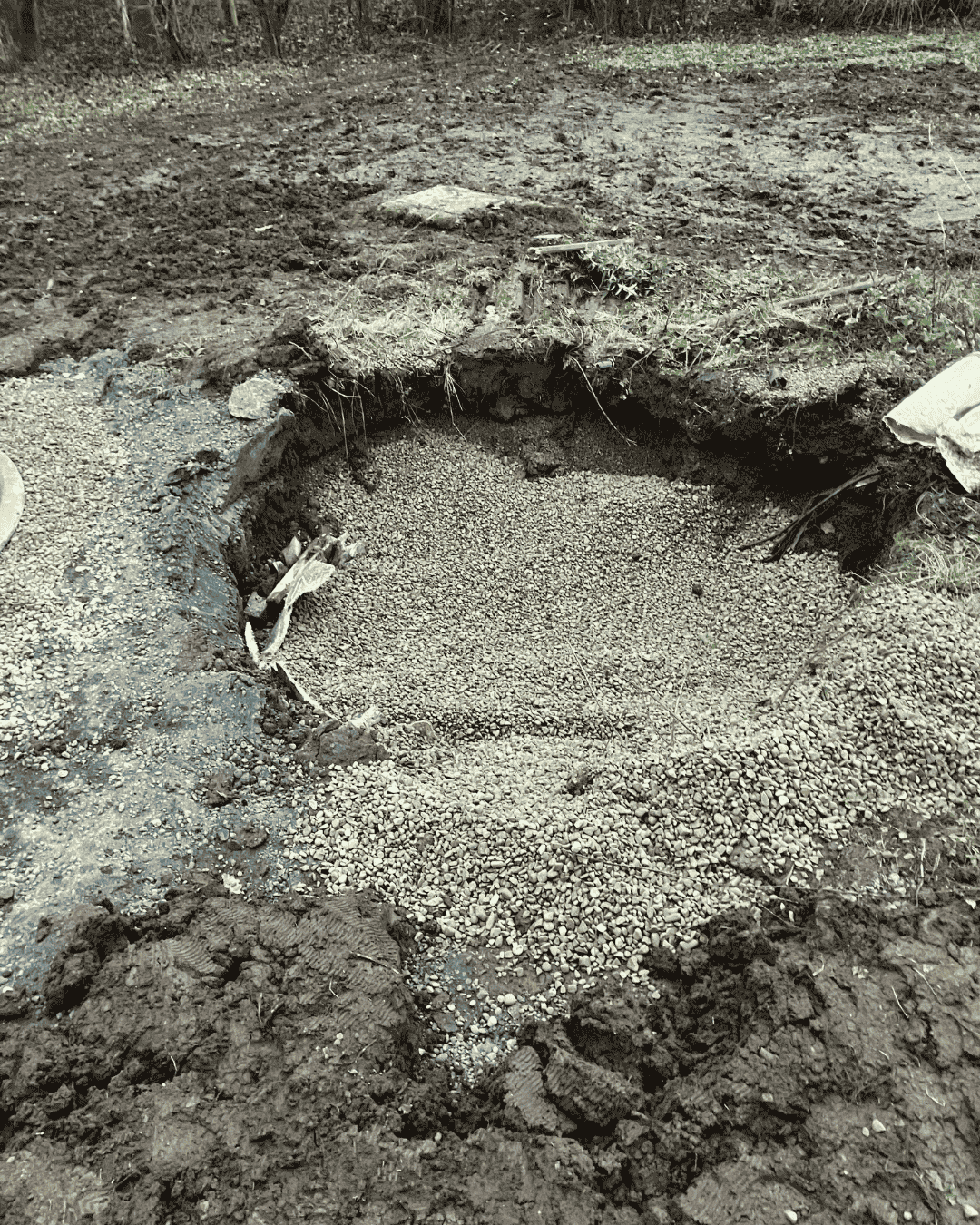

As the final stages of installation wrapped up, attention turned to restoring the site. The old tank was emptied and filled with gravel before being covered with excavated soil. Any surplus soil was removed via grab wagons. The system was then powered up, tested, and commissioned, ready to handle the demands of our clients growing operations.

A Future-Ready Solution

The result was a wastewater treatment solution built for the future. With the new BioDisc and effluent pump station in place, the facility could operate efficiently without fear of overloading the drainage system. Through careful planning and expert execution, our engineers delivered a seamless upgrade that met regulatory standards and ensured long-term reliability for the client.

For more information on wastewater treatment solutions, contact us today.